Flexible Circuits

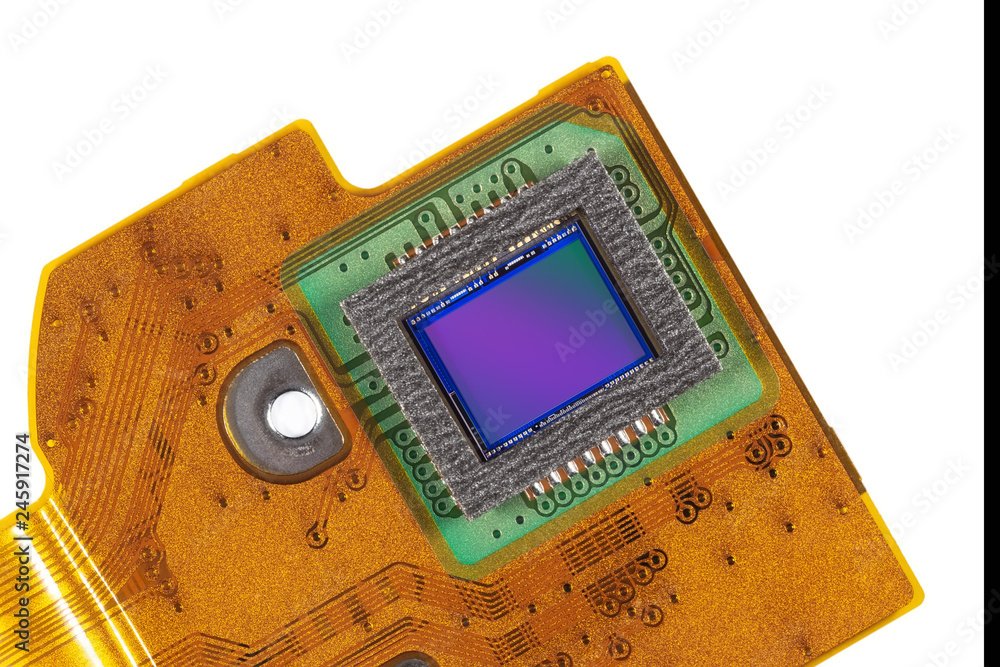

Flexible circuits, also known as flex circuits or flexible printed circuits (FPCs), are electronic circuits designed on flexible substrates, enabling them to bend, fold, and conform to various shapes without compromising functionality. This adaptability makes them ideal for applications where traditional rigid printed circuit boards (PCBs) are unsuitable.

Flexible circuits have revolutionized electronic design by offering versatile solutions that traditional rigid PCBs cannot provide. Their unique properties enable the development of innovative products that are lighter, more compact, and capable of withstanding demanding environments.

Key Components

Flexible Substrate: Typically made from materials like polyimide , these substrates provide the necessary flexibility and durability.

Conductive Layers: Copper is commonly used for the conductive traces due to its excellent electrical properties and flexibility.

Protective Layers: Coverlays or solder masks are applied to shield the conductive traces from environmental factors and mechanical damage.

Advantages

Space and Weight Reduction: Their ability to conform to tight spaces allows for more compact and lightweight electronic designs.

Enhanced Durability: Flex circuits can withstand vibrations and dynamic movements, making them suitable for applications requiring repeated flexing.

Improved Reliability: By reducing the number of interconnects and solder joints, flex circuits can decrease potential failure points in electronic assemblies.

Common Applications

Consumer Electronics: Used in devices like smartphones, tablets, and wearable technology to connect components within limited spaces.

Automotive Industry: Employed in instrument panels, under-hood controls, and lighting systems due to their resilience to harsh conditions.

Medical Devices: Integrated into diagnostic and monitoring equipment where flexibility and reliability are critical.

Aerospace and Defense: Utilized in avionics and communication systems where weight savings and durability are essential.